A regular concrete floor can crack, stain or just look bad while epoxy has additives in it which can last a lifetime if well maintained. Over the last few years, several types of epoxy have been used on garage floors including epoxy garage floor paint, garage floor epoxy coating, metallic epoxy coating, epoxy coating with flakes and epoxy coating with a polyaspartic topcoat which is added for durability purposes.

Table of Contents

Understanding Garage Floor Epoxy

Epoxy resin is a versatile substance that can be used in a wide range of situations, in this case, epoxy is used as a floor coating. Epoxy floor paint is not really a true epoxy, it is mixed with acrylic which makes it chemically different from epoxy coatings.

Epoxy Resin holds up well and offers a practical cost-effective solution for garage flooring. This type of flooring comes in a few different forms. The major consideration is to choose between a garage floor epoxy coating or epoxy garage floor paint. Both offer unique advantages and finishes.

What’s The Best Garage Floor Epoxy

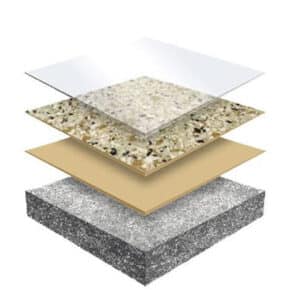

Epoxy garage floor coating with flake and a polyaspartic topcoat is the most durable garage floor coating. It is important that the concrete surface is properly prepped before the epoxy coating is applied so that it adheres to the concrete. Once the epoxy is applied, then flakes are added, the epoxy base coat then needs to dry and the polyaspartic topcoat is added. This process is slightly different than a metallic epoxy floor application which is also a great choice. Metallic epoxy floors entail multiple colors of epoxy applied and mixed during the base coat, then covered with a polyaspartic topcoat to make it durable and impervious to scratching.

Epoxy Garage Floor Installation process

Surface Preparation

The main reason that epoxy floors fail is a result of bad concrete floor preparation The first step is to make sure that the concrete is in good condition and ready to take the floor coating. We grind the concrete with diamond blades, removing the top layer of concrete so it is open and porous enough that the epoxy resin can seem into it and form a bond. After grinding the floor, crack repair and any imperfections need to be addressed.

Protecting The Area

Epoxy can be a very difficult substance to remove and clean up if it cures. For this reason, make sure that your work area is properly protected. Use masking tape and plastic sheeting to cover any walls, furniture, and fittings that you don’t want to mess epoxy on.

Mixing The Epoxy

Now the floor is ready for application. Start by getting all of your materials and tools ready. You need to make sure that you have everything available because once the epoxy is mixed you have a limited working time before it hardens.

When prepared and ready to go, you can mix the epoxy components according to the manufacturer’s guidelines. This needs to be thoroughly mixed to get good results. You can also add in any color dyes or flakes at this point.

Applying The Epoxy

Epoxy is applied using a special epoxy roller brush. The epoxy is poured out and then backrolled to make sure the coating is spread evenly throughout the entire concrete surface.

The drying time will depend on the product that is applied and the environmental conditions but on average it will take anywhere from 4 hours to 24 hours to dry. Once fully cured, you can add a second coating. Just follow the same process as above.

Applying A Top Coat

Once all of the epoxies have been applied and cured, it’s time to finish the floor with a topcoat. This can be either epoxy, polyurethane, or polyurea or polyaspartic. A clear topcoat offers more durable protection for a longer-lasting finish. Apply this evenly and smoothly and let the floor cure completely before using it. This may take up to three days.

Lifespan Of An Epoxy Garage Floor

Epoxy garage floor coatings can last as long as the concrete is intact as long as it is cared for properly. A well-applied epoxy garage floor with a solid concrete slab can outlive a human and will remain attached to the concrete forever if it is cared for and not exposed to direct sunlight or acidic chemicals. The typical period for a garage floor is 20 years.

Call Paradigm Concrete Finishes For The Best Epoxy In Florida

Paradigm Concrete Finishes is located in Sarasota Florida and provides epoxy floor coatings all over the state of Florida as well as polished concrete and concrete preparation services including crack repair and glue and mastic removal. Call us today if you have a flooring project that you need done right! The garage floor paints and epoxy floor kits sold at big box stores will not withstand the test of time like a paradigm concrete finishes